Project Description

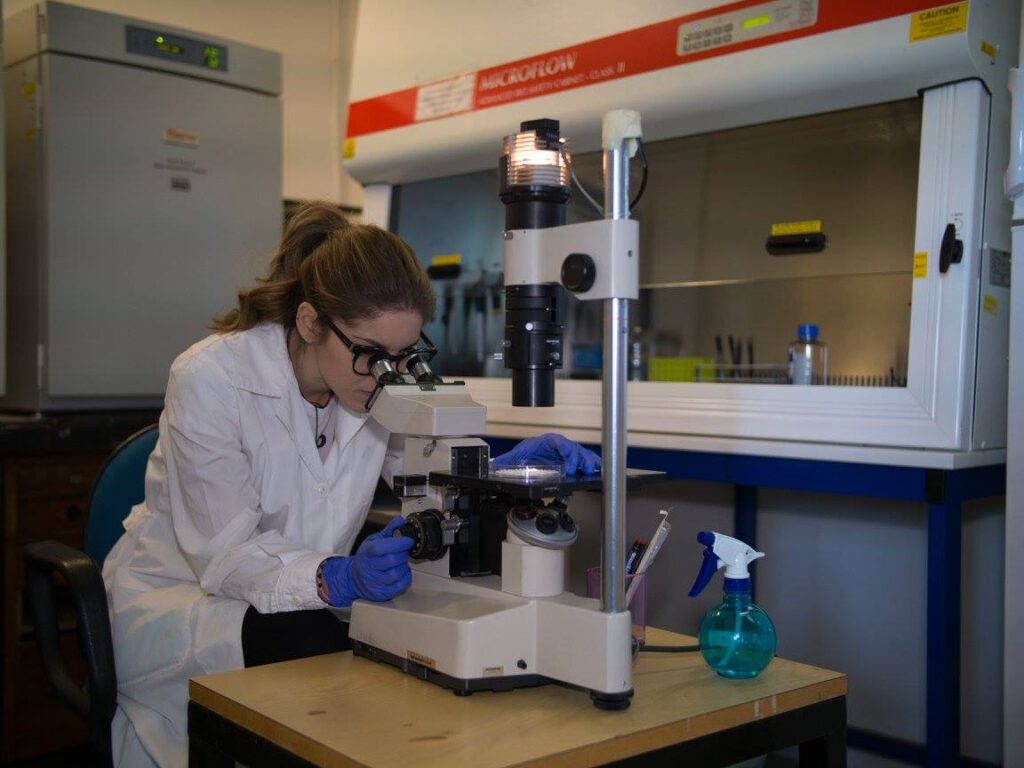

- Construction of Cleanroom with purity class ISO 7 (at operation) according to ISO 14644 for the company Pleioflow, in which medical devices will be produced and assembled.

- Construction of auxiliary spaces such as staff dressing area and storage of raw materials and final product that also function as clean areas ISO 8 at operation

Life Science

Kifisia, Athens

2021

| Area | ISO Class / GMP Class (at operation) | Nessecary Conditions T & RH | Surface | Overpressure |

| (-) | (-) | (°C) / % | (m2) | (Pa) |

| MAL | ISO 8 / GMP C | T: 23 ± 2oC, RH < 60 % | 4.2 | +15 |

| PAL | ISO 9-8 / GMP D | T: 23 ± 2oC, RH < 60 % | 6 | +20 |

| Main LAB | ISO 7 / GMP C | T: 23 ± 2oC, RH < 60 % | 19.5 | +25 |

All spaces are made of polyurethane PANEL with smooth outer lining on both sides, 50mm thick. The joints of the panels were sealed with special silicone so that no recess appears.

A watertight suspended ceiling suitable for clean spaces was installed in a standard structure under a grid of 1200×600 mm. Its configuration was done with heavy-duty aluminum profile dimensions 60×40 mm 2mm thick.